Pumping Principle

Twin Screw Pumping Principle

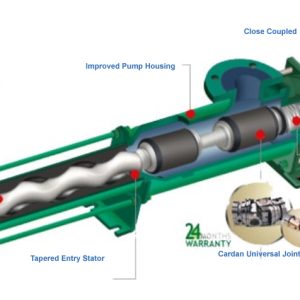

The working principle of Roto Gear Timed Dual – Flow Twin Screw Pumps is dependent on the rotation of two screw spindles in closed compartment. Wherein, a predefined clearance is maintained between the screw spindles as well as between the outside diameter of the screw spindles and the bore of the casing/liner in which the screw spindles are located. Each half of the screw spindles is left-handed and right-handed. Thus, when the spindles start rotating, driven by a pair of timing-gears located at the end of the screw spindles, the liquid is drawn towards the end of the screw spindles and entrapped between the bore of the pumping compartment as well as the flanks of the screws and is then propelled axially from both the ends towards the centre. Such a dual flow nullifies the axial thrust completely thereby enabling the screw spindles to remain in a state of hydraulic balance. Roto’s unique double profile of the screw spindles contributes to a higher volumetric efficiency, thus an improved overall efficiency.

Reviews

There are no reviews yet.